As Petcube is getting closer to the assembly line predictably more unpredictable issues pop up on our glorious quest to mass production. At the end of the day, it’s all about hardware. Mainly because it is hard and the second reason turned out to be the money. Manufacturers keep surprising us by raising prices for almost every component and we spent weeks fighting back and improving our BOM (Bill Of Materials) without cutting off any of Petcube’s features. We saw this coming, so now we are well prepared to anticipate it.

We’re getting really close to molding our dream (literally). Just a small explanation for everyone who isn’t familiar with the manufacturing process: all the Petcube’s plastic parts will be shaped with injecting the molten polymer into massive steel molds.

Producing plastic injection molds is a complicated process because we need 18 original parts and 7 molds to make them. And it’s even harder when everybody keeps speaking Chinese ;) We are finishing the paperwork to start tooling next week. Unfortunately we spent an extra month tuning the mechanics for our laser control system because we needed to be super careful here. You can’t really change a thing when it’s already molded. By the way here’s how the most complex Petcube part looks like:

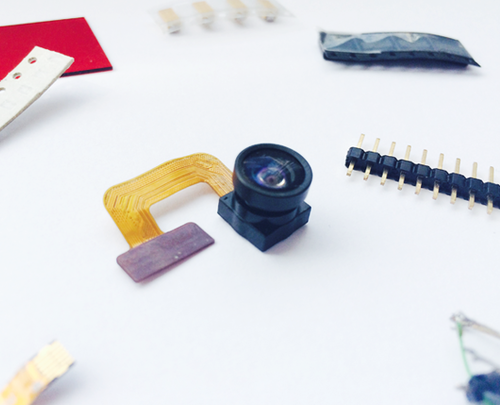

Another challenge for us was sourcing the right camera. We needed to go deep into low level programming and work closely with manufacturer engineers adjusting software drivers for a few extra weeks.

After considering up to 20 options we finally have a winner — Himax camera proved to be the best one. 5 megapixel CMOS sensor and 138 degree optic lens on board.

While testing we had to put a special color palette in different light conditions and check if the video displays various colors in the same way as we see them with our own eyes. No mixing up turquoise and seafoam green anymore! Just joking. We mean, there are no turquoise cats, right?

A picture of some of the Petcubers taken with a Petcube camera. Head engineer Igor on the left is not impressed with quadrocopter.

Yet another bump you can’t avoid hitting with such a hot piece of technology is temperature. The magnetic coils on our PCBs tended to overheat. That resulted in extra 2 weeks of testing and solving the issue with software adjustments and reducing the power on the coils. On the bright side you won’t be seeing any of this.

Draft design of a back panel with too many vents.

Unfortunately, all the things above slowed us down quite a bit. With a heavy heart and other body parts that are extremely tired we announce a second delay.So the new estimated shipping time is October. This is bad and we feel bad. But under no circumstances will we ship a bad product. We believe the good one is worth waiting and fighting for. There are also good updates to cheer you up a bit.

With tons of coding done right we’ve finally switched over from server-based to P2P (peer-to-peer) video streaming. This change helps us a lot in minimizing delay and traffic.The video now uses its shortest way from Petcube to your smartphone bypassing any additional services, which makes its trip much faster and safer.

When it comes to hardware, you can never have too much testing. As mentioned earlier, we’ve been checking our mechanical platform a lot, and it’s working really well. And it will do even better after the plastic parts are molded and have a perfect precision — that is something we are greatly anticipating these days.

There is still a lot to be done, and your support is very important. Thank you for being with us all this time. Just so you know we have the same passion as we did 20 updates earlier, but we’ve got less naive and more badass. With your help Petcube is gonna be out there. For now we have this Chinese cube shaped watermelon as a placeholder.